Selective leaching

What we do

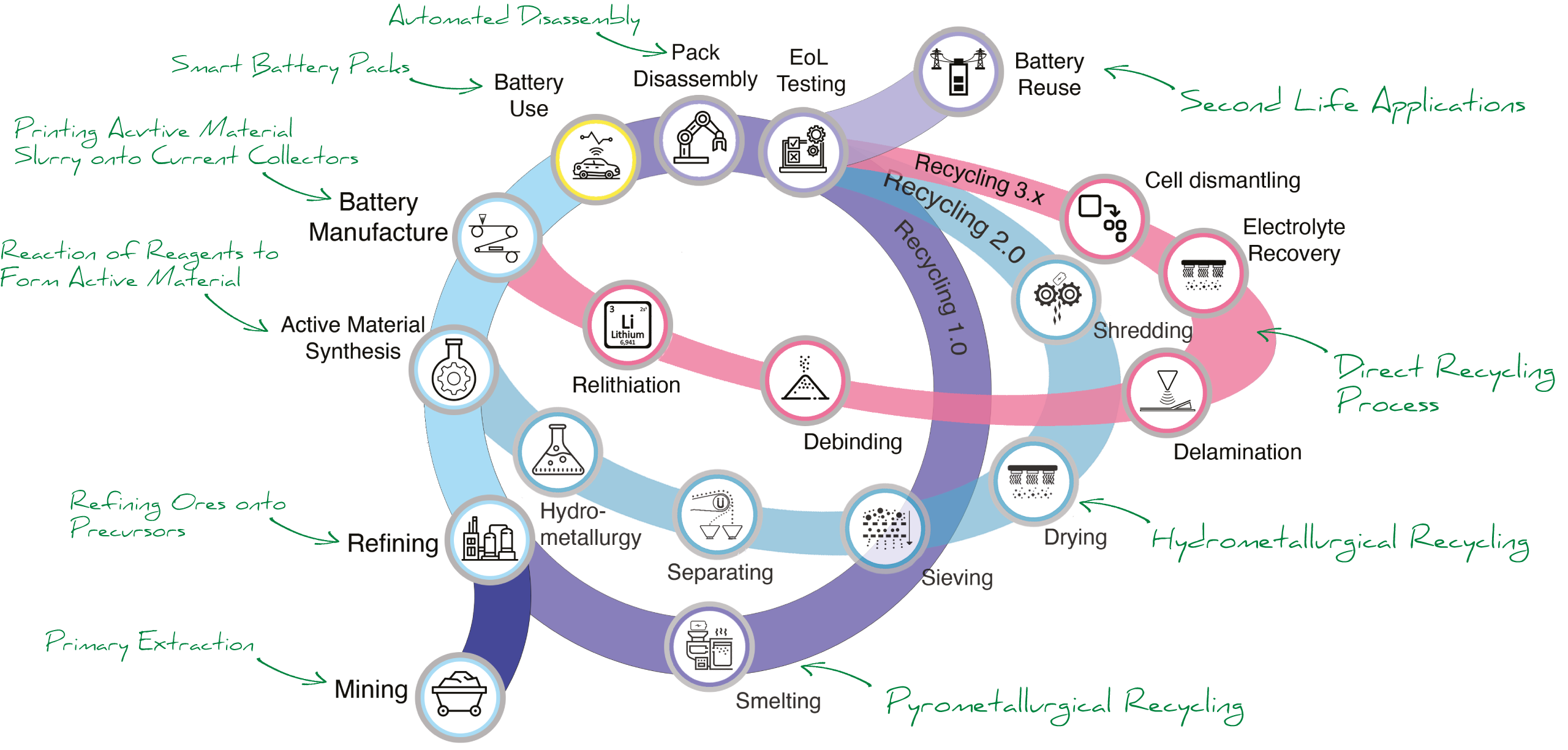

Selective leaching could play a significant role as the increase in production of electric vehicles increases demand on critical elements, by helping the efficient recycling of valuable materials from end of life EV batteries, reducing the pressure on resources and minimising waste.

The cathode material is the highest value component of the battery and has attracted significant corresponding interest for recycling. Most recycling methods involve dissolving all cathode material in an acid, which then needs purification and separation steps to recover individual methods.

This approach becomes even more complex if the cathode contains two different materials (blended cathodes) or if the recycling stream contains Li ion batteries from different sources with different chemical compositions.

How we work

ReLiB researchers at the University of Birmingham have developed a phase selective leaching method to recycle, upcycle and regenerate cathode materials.

The process, which has been successfully demonstrated on end of life EV batteries, uses phase selective leaching to separate Mn-rich phases from mixed and blended cathode materials, including mixtures with common battery electrode materials, such as NMC, NCA, LFP.

These phases can be regenerated or, due to the adaptability of the process, can be upcycled to next generation cathode materials. By combining this with a direct recycling approach also known as “cathode to cathode recycling”, the remaining high value Ni and Co rich phases can also be recovered and regenerated.

It also has the added benefit that it can meet future requirements for Na ion battery recycling and potential next generation high capacity disordered rock salt Li ion battery materials. A patent has been published (Patent no. (WO/2022/084668)) on this phase selective leaching and regeneration processes.

Results achieved

The ReLiB process can deal effectively with complex mixtures of materials, which are likely to be present in recycling waste streams due to changing battery chemistries.

Shredding

What we do

ReLiB are at the cutting edge of innovation around dealing with “black mass”, the toxic mix from the insides of battery cells that have reached the end of their useful lives.

This dark powder and the valuable metals within it will play an increasingly important role in the decarbonisation of the world economy over the coming years as the adoption of electric vehicles continues to grow.

ReLiB is at the forefront of the “shredding” techniques needed for the circular process take electric car battery materials from old to new.

How we work

Shredding and sorting processes are widely used in lithium-ion battery recycling, to separate out materials which already have well-established recycling routes, such as steel casings, aluminium foils and copper foils, solvents, and plastics.

The remaining “black mass” comprises of the most valuable and critical components in a lithium-ion battery, namely nickel, manganese, cobalt, lithium, and sometimes graphite.

This is sent for extraction processes to separate the metals into high purity salts used as precursors in the manufacture of fresh batteries.

To maximise the materials which are recycled and reduce the costs and energy requirements of extraction processes such as hydrometallurgy it is important to minimise extraneous materials being put in to extraction processes.

This can be achieved by using processes which produce a free flowing material to be put through physical separation processes.

Our technologies produce separate streams of anodic black mass, primarily graphite, and cathodic black mass, which is nickel, manganese, cobalt and lithium, or lithium iron phosphate, which are higher in purity and allow for more effective extraction processes.

Results achieved

Contemporary shredding and sorting processes use density and magnetic separation processes to remove plastics and casings, and fine milling and screening to remove foils and produce black mass which is quite contaminated with other materials.

Sensing technology

What we do

ReLiB partners are providing a sorting scheme to be central to a reliable gateway testing strategy, which will be paramount in the EV battery recycling industry as it not only relies on battery management system data but looks to provide detailed information about the status of each individual module or cell.

Providing this information will decide whether each battery cell or module can be reused in an EV, reutilised in less demanding applications or is not economically viable and must be recycled.

How we work

ReLiB partners in the research team at Newcastle University have developed a practical sorting scheme that uses electrical and thermal sensing technologies to evaluate the health of retired EV batteries.

The feasibility of the developed scheme was validated on different original equipment manufacturer (OEM) form factors such as Nissan Leaf and Tesla batteries.

For electrical sensing technology, the developed scheme reduced the test time to minutes instead of hours, with only the terminal voltage and discharge current being used, providing great potential and practical significance to the battery recycling industry where the cost and time are dominant.

Developed thermal sensing techniques, based on infrared (IR) thermography provide insight into spacious battery ageing. The techniques were successfully applied to EoL battery pack LiBs characterisation, LiBs second-life “real” EoL detection and orientation influence on battery ageing.

The partners have also developed thermal sensing techniques which can be coupled with different spacious characterisation techniques such as CT, acoustic and XRD, to be integrated with developed electrical sensing techniques into the production line for fully automated contactless and non-destructive sorting.

Results achieved

The ReLiB applied sensing technology provides insightful information related to the degradation mode of the battery that can aid the reassembly of cells and modules to form a homogeneous battery pack for repurposing in energy storage applications or reuse in EVs.

Engineering biology

What we do

ReLiB is at the cutting edge of biological processes for enabling and or supporting the development of more sustainable metal separation methods for electric vehicle battery components.

ReLiB has the expertise to lead the way on synthetic biology, which is the design and construction of biologically based parts, novel devices and systems as well as the redesign of existing, natural biological systems. Engineering biology is the process of taking synthetic biology concepts and translating them into solutions to the problems people and the planet face, now and tomorrow. As such, synthetic biology and engineering biology are responsible for disruptive innovation in a wide range of sectors, including therapeutics, agriculture, food & drink and renewable energy.

How we work

In the present project, the use of synthetic biology seeks to increase the synthesis of natural and synthetic biomolecules for the improved separation and recovery of metals in the form of nanoparticles.

Scientists and engineers are using DNA, RNA and proteins as the building blocks with which to construct new processes, processors and products.

The rapid rise in the affordability of DNA synthesis has driven the field to advance at an impressive pace.

Bio foundries provide researchers with access to robotic liquid-handling equipment, high-throughput analytical equipment and the software, personnel and data management systems to build and test large numbers of DNA constructs to quickly learn how they might produce the desired effect.

ReLiB’s engineering biology approach capitalises on the sensitivity and selectivity of biological processes to offer an alternative to current metal recovery methods.

Results achieved

Two strains of bacteria have been engineered to improve their selective biosynthesis of metallic nanoparticles and their sequential application has enabled us to establish the first steps of a bio separation and bio recovery process for the metals contained within spent lithium ion batteries.

Tomography

What we do

The Electrochemical Innovation Lab (EIL) at UCL specialises in imaging and diagnostics for a wide range of energy storage devices.

These technologies allow the materials degradation and state of health of batteries to be examined, non-destructively.

Collaborating with other academic partners in the ReLiB programme under the auspices of the Faraday Institution, we are developing bespoke diagnostic and imaging techniques to evaluate the state of health of end-of-life batteries disassembled from electric vehicles to assess their suitability for secondary application.

How we work

Our diagnostic tools include 3D x-ray imaging, thermal imaging, acoustic imaging and 3D laser imaging, alongside electrochemical impedance spectroscopy (EIS).

The EIL boasts a world-leading centre for correlative x-ray imaging using state-of-the-art equipment for radiography and computed tomography to be used in scientific and industrial research.

It offers a world leading suite of 3D x-ray imaging facilities, which produce high-quality 3D images at different length scales.

Our x-ray computed tomography (X-ray CT) is a uniquely non-destructive technique across multiple length scales, with resolutions ranging from 10s nm to 10s mm, and sample sizes from 10s micron to 10s cm.

Because of its non-destructive nature, researchers can probe material structures during their life cycle in response to a variety of conditions with so-called ‘4D’ tomography, incorporating three dimensions in space, and one in time, for the characterisation of microstructure evolution processes.

Results achieved

The centre equipment includes:

- Nikon XTH 225 (high energy micro-CT) which can accommodate large samples with sizes of up to ca. 50 cm and weights up to 15 kg. It can achieve a spatial resolution of ca. 5 µm.

- TESCAN UniTOM HR (high speed micro-CT): With fast frame rate detectors and high flux sources, it maximises throughput and reduce the cost per scan. It can achieve a spatial resolution of 600 nm.

- Zeiss Xradia Versa 620 (high-resolution micro-CT): A 3D x-ray microscope using a two-stage magnification technique that can achieve a spatial resolution of 500 nm.

- Zeiss Xradia Ultra 810 (highest resolution nano-CT): With a quasi-parallel beam, it provides spatial resolutions < 100 nm in 3D using absorption and phase contrast techniques.

Ultrasound delamination

What we do

ReLiB researchers at the Universities of Leicester and Birmingham have solved a critical challenge in the recovery of materials used in electric vehicle batteries at the end of their life, enabling their re-use in the manufacture of new batteries.

The new method, which uses ultrasonic waves to separate out valuable material from the electrodes, is 100 times quicker, greener and leads to a higher purity of recovered materials relative to current separation methods.

How we work

One key stumbling block has previously been in materials segregation, namely, how to remove and separate the critical materials such as lithium, nickel, manganese and cobalt from used batteries in a fast, economical and environmentally-friendly way.

The ReLiB team in Leicester and Birmingham devised a novel ultrasonic delamination technique that blasts the active materials from the electrodes leaving virgin aluminium or copper, which proved highly effective in removing graphite and lithium nickel manganese cobalt oxides, commonly known as NMC.

Materials recovered using the technique were found to have higher purity and therefore higher value than in conventional recycling approaches and are potentially easier to use in new electrode manufacture. The approach is fast and adapts technology in widespread use in the food industry.

The likely initial implementation of the technology will use production scrap from battery manufacturing facilities as the feedstock and feed recycled material straight back into the production line, possibly at the same site. This could be a real step change in battery recycling.

Rather than the conventional use of concentrated acids in a batch immersion process, our ultrasonic technique is a continuous, feed process that uses water or dilute acids as the solvent so the technique is greener and less expensive to operate.

It can delaminate 100 times more electrode material in a given time and volume than existing batch delamination techniques. More information is available here: Video 1, Video 2, Infographic.

Results achieved

Current recycling methods for lithium-ion battery recycling typically feed end-of-life batteries into a shredder or high-temperature reactor, with processes needed to produce useable streams of the lithium, cobalt, nickel and copper, which is energy intensive and inefficient.

In Direct recycling, by relithiation method, the spent cathode from the Eol EV battery is converted to a high value cathode to create new Lithium-ion batteries. In this process, the cathode maintains its original structure and purity to the maximum extent. The process is cost-effective, consumes less energy, is eco-friendly, and is a beneficial addition to EV battery technologies.

If end-of-life batteries are disassembled rather than shredded there is the potential to recover a high yield, around 80% of the original material, in a purer state than using shredded material.

With automakers realising the importance of recycling considerations in product design to create a circular economy for battery materials, designing for recycle will mean raw materials can be returned to the manufacturing process at potentially half the cost compared with primary sources.

Robotics

What we do

ReLiB is playing a leading role in shaping the future of disassembling EV batteries using robotics.

Unlike assembling EV batteries, automating disassembling cannot be solved through pre-programmed repetitive motions due to the many different battery styles, makes and models. As a result, recycling plants have not developed automated disassembling lines.

The implementation of a circular economy requires logistics and processing activities involving batteries, which presents a significant challenge when it comes to maintaining safety throughout the value chain.

The robotics team of the ReLiB project, led by Professor Rustam Stolkin and Dr Alireza Rastegarpanah, are making progress on the automating processes for the testing, disassembly and sorting of EV batteries by use of robotics.

How we work

As part of the ReLiB project, we are developing fully autonomous and semi-autonomous manipulation “action primitives”. The manipulation primitives are capable of self-configuring according to battery formats, planning, and learning.

Results achieved

As part of the ReLiB project, a unique heavy-duty industrial robot test-bed is being assembled at the University of Birmingham’s Birmingham Energy Innovation Centre (BEIC) at Tyseley Technology park. This nationally unique infrastructure enables advanced robotics research methods to be developed, implemented and demonstrated on full-scale industrial machines.

Robotic disassembly and robotic gateway testing can be performed at various scales, such as unscrewing, cutting, grasping, moving, connecting and disconnecting. ReLiB are developing advanced human-robot interfaces to enable human workers to directly control remote robots with artificial intelligence (AI) assistance, enabling human teaching of new autonomous behaviours.

ReLiB seeks partnerships with like-minded people and is inviting collaborations to improve LiB recycling and address challenges in the electric vehicle industry.

Academic frontier research

What we do

ReLiB is made up of 7 research intensive UK universities. Our universities are world leaders in discoveries linked to the recycling and re-use of lithium-ion batteries. Moreover, we are also a group of dynamic thought leaders, contributing to global and domestic policy matters linked to the Net Zero agenda specially aligned to decarbonising global transport systems.